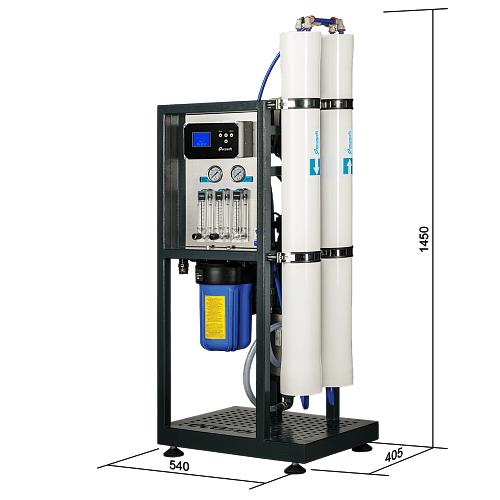

Ecosoft MO 12000 Econnect Commercial Reverse Osmosis System

2.750,0 KWD

- Online Monitoring System

- Up to 3200 gallons of pure water per day

- Effective solution to water problem

- Original attractive design and small size

- Simple maintenance

- Low energy use

You can enjoy all the benefits of premium-quality water with the Ecosoft MO12000 Commercial Reverse Osmosis System. This is the most advanced and effective method to remove up to 99.8% of impurities, including bacteria and viruses. Reverse osmosis is an eco-friendly and cost-effective way to obtain safe drinking water.

The system is a compact, fully functional unit.

The new unique ECONNECT feature transforms the commercial reverse osmosis water purification system into a modern smart device.

Each user has a personal online guide containing complete information about the system:

- Statistics: Effectiveness and process analysis

- Status: Real-time system status

- Remote settings adjustment capability

In addition to the main information about the quality of feed water and the amount of purified water, the online personal guide keeps data available on the membrane element’s effectiveness and condition.

A new multifunctional controller, the OC6000, is installed in every Ecosoft MO 12000 Econnect commercial reverse osmosis system. It sends all available data to the online personal guide.

Model Features:

- 100% Protection

- Up to 12,000 liters of pure water per day

- Continuous monitoring of purified water quality

- Compact and fully automated

- High-quality components from leading manufacturers

- High-pressure pump with low vibration noise

- Optimized OC6000 controller for continuous independent system operation

OC6000 Controller Arm – Best Professional Maintenance Capabilities:

- Measures flow rate and volume of purified water;

- Monitors feed water and treated water quality;

- Determines purified water discharge method;

- Remote firmware updates.

Maintenance:

Thanks to the ECONNECT feature, system maintenance becomes easier and more effective!

The system operation and maintenance log in the online personal guide allows for efficient and timely filter replacements, chemical cleaning of membranes, and other system maintenance activities.

- Replace sediment filters – at least once every 3 months.

The sediment filter protects the reverse osmosis membrane from large impurities such as sand, clay particles, etc. With ECONNECT functionality, you will always know when to replace it. Now, the membrane element and your system will last longer.

- Perform RO membrane chemical cleaning – at least twice a year.

CIP should be performed if the quality of purified water deteriorates or capacity decreases, which you can monitor in the online personal guide. CIP is carried out using the chemical cleaning unit and cleaning chemicals.

You no longer need to keep a maintenance log for the system!

Timely maintenance extends the lifespan of the equipment, while also providing pure and safe water of the highest quality.

Who is this product for?

The Ecosoft MO 12000 Econnect RO system is designed for water purification in:

- Hotels, cafes, and restaurants

- Breweries and bakeries

- Laboratories and workshops

- Car washes

- Small industrial processes

- Steam boilers and heating and cooling systems